Some techniques can be used to replace existing pipes such as asbestos cement, non-reinforced concrete, and PVC conduits.Ability to drill beneath surface obstructions or ongoing site operations.Ideal for sites sensitive to surface disruption such as heavy roadways, airport runways, golf courses, etc. Limited traffic and landscape disruption.Weather will not impact directly on the process.Reduces the excavation and shoring costs.The directional drill produces twice the amount of oil or gas being extracted.

Protects the ecosystem and adjacent areas.Reduces the contamination of groundwater pollution.Reduces the fractures to existing rock formations.

Directional drilling cost install#

A single location area can be used to install different pipes. What Are the Benefits of Directional Boring? If you are looking for minimal damage to your existing ground, directional boring is the method to be used. In some circumstances, a drill can be set up on the side of the road, and the only disturbance will be from the footprints of the locator. For the most part, horizontal directional drilling will only disturb the location the machine is set up at and any place that utilities need to be connected. It normally causes minimal disturbances but can be a situation where sod or grass seed needs to be replaced in those areas. The water will usually tend to come up to the surface of the ground. The horizontal directional drilling machines-made by companies such as Vermeer-are heavy, run on tracks and tend to disturb or damage the area below them or where they transit.Īnother area that will cause some trouble is the water used for the boring. There is still damage that is done as with all construction equipment, but proper planning and patience can keep it to a minimum. If we wanted to choose one over the other without cost as a factor, directional boring or horizontal directional drilling would be selected as the best alternative, doing everything trenching and plowing can do and jobs once thought impossible before this great technology.Ĭonstruction Footprint of Directional Boringĭirectional boring usually has a lower impact on the existing ground meaning a lot less of the existing is disturbed. These two technologies usually compliment each other trenching or plowing being more cost-effective but having limitations and directional boring taking care of everything else but at a higher cost. The installation cost for trenching versus directional boring is usually lower, in the range of six to eight times less than horizontal drilling. Directional boring can be used in the same situation where open cut excavation is planned, but it can also be used to go under roads, sidewalks, rivers, even houses if there is a need for it. This method can only be used when the ground above the utilities can be disturbed and there are no buildings, roadways or other obstructions in the way. Open cut, or trenching, is the most common way to install and connect utilities, but it has some limitations. Directional drilling goes above and beyond traditional trenching connecting utilities and services in places that traditional trenching is impossible.ĭirectional Boring vs.

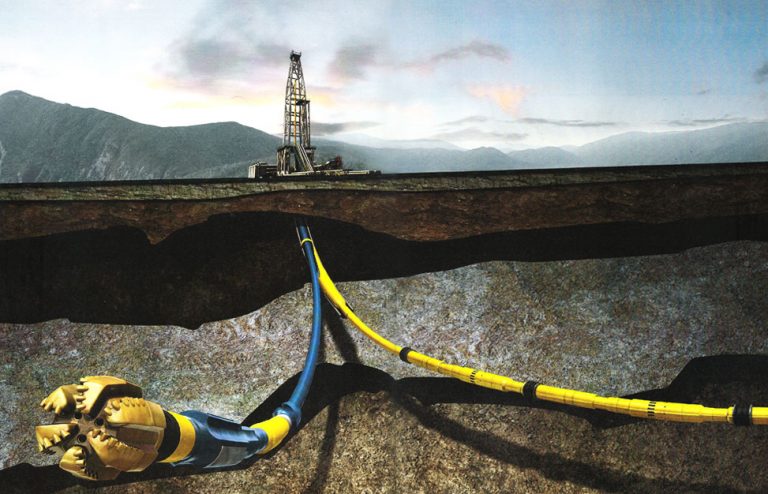

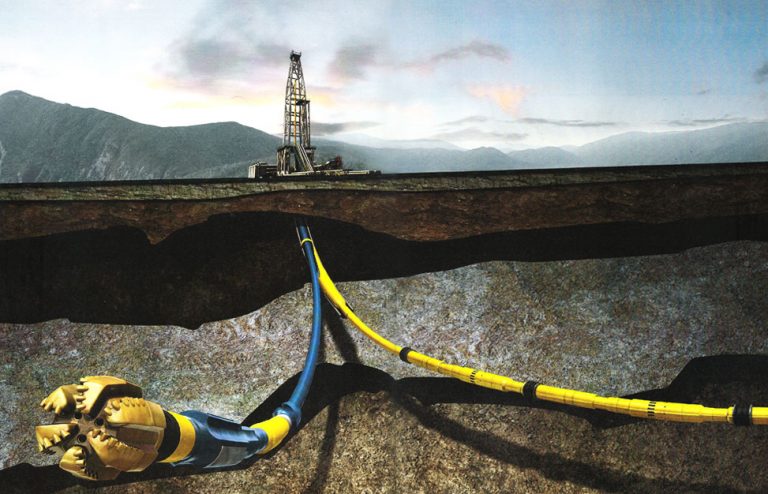

Directional boring is mainly used for making crossings under rivers, roads, and existing structures, with the purpose of installing pipes and conduits to transport different types of fluids and materials.ĭirectional boring or horizontal directional drilling is a way to get utilities from one point to another without destroying the existing ground or obstacles that are in between the two points. A pilot borehole is drilled along a pre-determined bore path from the surface with minimum disturbance. In the oil and gas industry, directional boring involves laterally drilling various wells through a zone of oil or gas-bearing rock at angles from a vertical well hole.ĭirectional boring or horizontal directional drilling is also used in the installation of utility pipelines and conduits. Continue reading below to learn more about directional boring and the benefits of this drilling method!ĭirectional boring, also known as horizontal directional drilling (HDD), horizontal drilling, slant drilling, or deviated drilling, is a method of trenchless technology. There is a multitude of benefits of directional boring including reduced fractures to existing rock formations and reduced cost.

0 kommentar(er)

0 kommentar(er)